Views: 0 Author: Site Editor Publish Time: 2024-12-18 Origin: Site

Solid State Relays (SSRs) are widely used in industrial and electronic systems due to their reliability and efficiency. However, when subjected to overload conditions, SSRs may exhibit various symptoms and consequences. Understanding these effects is essential to maintain optimal system performance and prolong the relay's lifespan. Below are the common effects of overload on SSRs:

Overloading an SSR increases power loss, leading to a significant rise in temperature. If heat dissipation measures are inadequate, this elevated temperature can compromise the performance and safety of the relay. Proper heat sinks or cooling systems are essential to prevent thermal failure.

SSRs equipped with status indication LEDs may display abnormalities under overload conditions. These include changes in LED brightness, flickering, or even complete failure to light up. Monitoring LED behavior can help diagnose potential overload issues.

When overloaded, the output voltage of an SSR may drop due to increased voltage drop across internal semiconductor devices. This voltage reduction can disrupt the normal operation of connected equipment.

Overloading affects the switching speed of SSRs, leading to slower response times. In extreme cases, the relay may fail to switch properly, impacting the timing and accuracy of operations.

Overload conditions can cause a surge in electromagnetic interference (EMI), potentially affecting the performance of other equipment within the same circuit or system. EMI mitigation strategies should be implemented to avoid system disruptions.

Prolonged overload accelerates the aging of the semiconductor components inside the SSR. This results in a shorter operational lifespan, requiring more frequent replacements and increasing maintenance costs.

Many SSRs are designed with built-in protection mechanisms, such as thermal or current protection. Under overload, these mechanisms may activate, placing the relay in a protective state to prevent damage. While this can safeguard the system, it may temporarily halt operations.

Severe or prolonged overload can cause irreversible damage to the internal semiconductor devices of the SSR, leading to complete failure. This underscores the importance of adhering to the relay's load rating.

Under overload, SSRs may generate additional noise, especially when operating with inductive or transformer loads. This noise can indicate stress on the relay and potential overload conditions.

In extreme overload situations, the SSR may lose control entirely, rendering it unable to respond to input signals. This failure can disrupt the entire system and necessitate immediate intervention.

To avoid these adverse effects, it is crucial to:

Operate within Load Ratings: Always ensure the SSR operates within its specified load capacity.

Implement Proper Heat Dissipation: Use adequate heat sinks or cooling mechanisms to manage temperature rise.

Monitor Load Conditions: Regularly check for signs of overload and take corrective measures promptly.

Utilize Overload Protection Features: Leverage SSRs with built-in protection mechanisms to safeguard the system.

By maintaining these preventive practices, you can enhance the durability and performance of your Solid State Relay and ensure uninterrupted system operation.

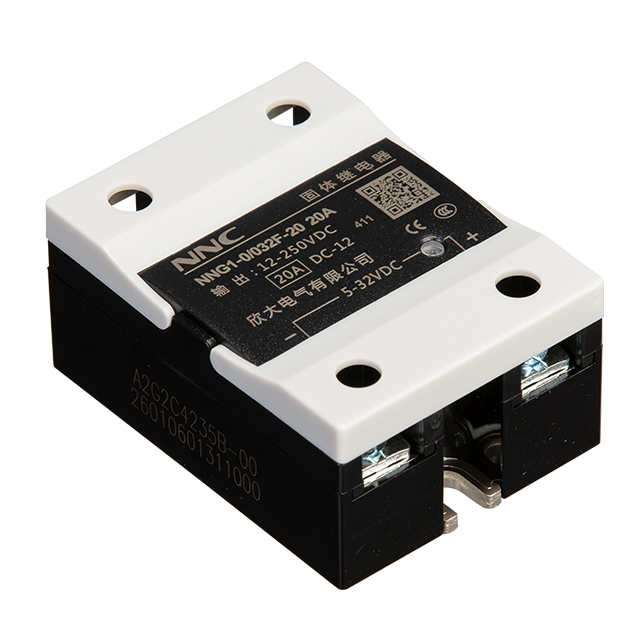

What is a Solid State Relay (SSR)? SSRs are electronic switching devices that use semiconductor materials to control electrical loads without moving parts. They are known for their high reliability, noise-free operation, and fast switching speeds.

Key Applications of SSRs:

Industrial automation

HVAC systems

Lighting controls

Motor drives

By understanding the effects of overload and implementing appropriate measures, users can ensure the reliable performance of Solid State Relays in various applications.