Micro switches are among the most widely used components in modern electrical and mechanical systems. Despite their small size, they play an essential role in a range of applications, from household appliances to industrial machinery. If you’ve ever pressed a button on a coffee machine or activated a limit switch on an industrial conveyor belt, chances are you’ve interacted with a micro switch.

In this article, we will explore how a micro switch works, its internal structure, the different types available, and its widespread applications. We will also highlight the advantages of using micro switches and why they are often the component of choice in various industries.

A micro switch, also known as a snap-action switch, is a type of electrical switch that is known for its quick, reliable action. Unlike traditional switches that may require continuous pressure, a micro switch operates with a single, snap-like motion, offering both speed and precision.

At the core of the micro switch’s functionality is its mechanical actuator. This actuator is typically a small button or lever that, when pressed, triggers the switch’s internal mechanism. The key characteristic of a micro switch is that it uses snap-action technology, meaning the switch "snaps" into the ON or OFF position once the actuator reaches a certain point.

Here’s a step-by-step explanation of how it works:

Actuation: When pressure is applied to the actuator (either by pressing a button, moving a lever, or pushing a plunger), it causes the internal mechanism of the micro switch to activate.

Snap-Action: Inside the micro switch, there is a flexible metal spring or contact arm that is bent or compressed. As the actuator moves, it applies pressure on this spring, causing it to snap past a set point. This is the “snap-action” that gives the micro switch its name.

Electrical Contacts: When the actuator causes the spring or contact arm to snap, it closes or opens the internal electrical contacts. This completes or breaks the electrical circuit, turning the device on or off.

Deactivation: When the actuator is released, the spring returns to its original position, and the switch reverts to its default state (either ON or OFF, depending on the switch's design).

Micro switches are often favored for their high-speed response, precise control, and long lifespan, making them ideal for applications that require rapid, reliable switching.

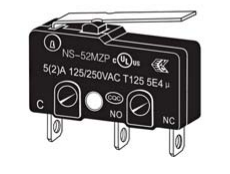

Understanding the structure of a micro switch is essential to grasp its reliability and effectiveness. Though the design may vary slightly depending on the manufacturer, the basic components remain the same:

Actuator: The actuator is the external component that the user interacts with. It can come in various forms, such as a button, lever, roller, or plunger. The actuator triggers the snap-action inside the switch when pressure is applied.

Housing: The housing is the outer casing of the micro switch that protects the internal components. It is typically made of durable plastic or metal, designed to withstand wear and tear, environmental factors, and electrical loads.

Contacts: Inside the switch, there are at least two contacts that open or close the circuit when the actuator is pressed. The contacts are often made of silver or copper alloys, materials known for their excellent electrical conductivity and corrosion resistance.

Spring Mechanism: The spring inside the micro switch is the critical part that enables the snap-action. It applies force to the contacts, ensuring a quick and reliable connection when the actuator is pressed. The spring is designed to return to its original state when the pressure is released.

Terminals: The terminals are the electrical connections where wires are attached. These terminals connect the micro switch to the circuit, allowing it to control the flow of electricity based on the position of the actuator.

Micro switches come in various types, each designed for specific applications. The most common types are:

Basic Micro Switches

These are the standard micro switches with a simple actuator and contacts. They are often used in household appliances like refrigerators, washing machines, and microwave ovens. These switches are ideal for applications requiring basic on/off functionality.

Roller Micro Switches

Roller-type micro switches have a small wheel or roller attached to the actuator. The roller helps distribute the force applied to the switch, making them ideal for use in mechanical systems like conveyor belts, elevators, and door mechanisms.

Lever Micro Switches

These micro switches feature a lever actuator that can be pressed or moved to trigger the switch. Lever micro switches are commonly used in applications where precise, mechanical movement is necessary, such as in control panels or machinery.

Subminiature Micro Switches

Subminiature switches are compact versions of the standard micro switch. They are ideal for applications where space is limited but reliability is still a priority. These switches are often used in electronic devices like printers, alarms, and small control circuits.

Waterproof and Sealed Micro Switches

These types of switches are designed to operate in harsh environmental conditions, such as extreme temperatures, humidity, and exposure to chemicals. They are typically used in outdoor or industrial applications where the switch may be exposed to the elements.

High-Current Micro Switches

These are designed to handle higher electrical loads, often found in industrial applications. They can control large motors, machinery, and other high-power systems.

Micro switches are used across a wide variety of industries, including:

Micro switches are found in many household devices, from coffee makers and washing machines to microwaves and dishwashers. They control the operation of these devices by sensing when doors or lids are opened or closed, ensuring safety and convenience.

In industrial settings, micro switches are used for control and monitoring purposes. They are commonly used in safety systems, such as limit switches on assembly lines, as well as for monitoring the status of machines, elevators, and safety doors.

In cars and trucks, micro switches control various systems, including door locking mechanisms, seat belt sensors, and brake light switches. They help ensure that critical safety systems function reliably.

Medical equipment, such as patient monitoring devices and medical infusion pumps, often rely on micro switches for accurate and responsive control. The precision and reliability of micro switches are critical in life-saving applications.

Micro switches are also used in keyboards, mouse devices, and remote controls. Their fast action and compact size make them ideal for these applications, where reliability and a quick response time are essential.

Micro switches play an essential role in alarm systems and motion sensors, where they detect the opening or closing of doors and windows or the movement of people within a space. This helps ensure the security of buildings and properties.

There are several key advantages to using micro switches in various applications:

Micro switches are known for their precise operation. The snap-action mechanism ensures that the switch operates consistently and quickly with minimal wear over time.

Due to their robust design and the nature of the snap-action mechanism, micro switches tend to last much longer than other types of switches. They can handle millions of operations, making them highly durable in demanding environments.

Micro switches are small and lightweight, making them ideal for use in tight spaces where traditional switches might not fit. Despite their size, they can handle substantial electrical currents and pressures.

The snap-action feature allows for very fast response times, making micro switches perfect for applications requiring quick activation or deactivation.

Micro switches consume very little power when operating, making them energy-efficient. This is particularly important in battery-powered devices like remotes or portable electronic devices.

Micro switches are inexpensive to produce and replace, making them a cost-effective solution for a wide range of applications. Their longevity and reliability also reduce maintenance costs in the long run.

Micro switches are incredibly versatile and reliable components used in countless applications across various industries. Their ability to provide precise, quick, and durable performance makes them essential for everything from home appliances to industrial machinery. With a broad range of types and applications, micro switches remain a cornerstone in the world of electrical switching.